- 로딩 및 언로딩

- 픽 앤 플레이스

- 원자재 및 완제품 이송

프레스 공정의 흐름에 맞춰

안정적이고 효율적인 자동화를 구현할 수 있도록 설계된 로봇 솔루션입니다.

프레스 로봇의 장점

프레스 및 펀칭용 로봇은 프레스 장비의 생산 효율을 크게 향상시키고,작업자의 안전성을 안정적으로 확보합니다. 반복 작업과 위험 공정이 많은 프레스 공정에서 로봇 자동화는 현대 제조 산업에 필수적인 솔루션으로 자리 잡고 있습니다

프레스 및 펀친용 로봇 적용분야

프레스 및 펀칭 로봇은 다양한 금속 가공 및 양산 공정에 활용됩니다. 자동차 차체 및 섀시, 연료 탱크, 라디에이터 핀, 각종 컨테이너 외함, 모터 및 전기기기용 규소강판, 계측기, 가전제품, 자전거, 사무기기, 생활용품 등

- 소형·경량 구조로 협소한 공간에서도 유연한 설치 가능

- 고속 반복 작업에 적합한 구조 설계

- 세계 최고 수준의 핵심 부품 적용으로 안정성과 신뢰성 확보

- 높은 동작 유연성

- 정밀한 반복 위치 정확도

- 안정적인 고속 운전 성능

- 용접

- 픽 앤 플레이스

- 조립

- 분류

- 로딩 작업 등

로보알바의 용접 로봇 시스템은 고객의 공정 조건과 요구 사항에 맞춰 맞춤형으로 구성할 수 있으며,MIG 용접, 아크 용접, CNC 연계 용접 등 다양한 용접 공정에 적용 가능합니다. 모든 용접 로봇은 ISO 및 CE 인증을 충족하여 안정성과 품질 기준을 동시에 확보하고 있습니다.

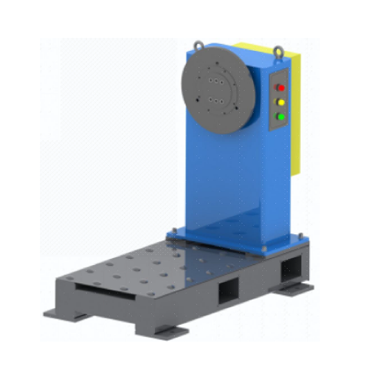

프레스 자동화 로봇의 장점

설치 유연성

바닥 설치형 및 상부(역방향) 설치형을 모두 지원하며, 효율적인 설치 및 초기 세팅을 통해 빠르게 현장에 적용할 수 있습니다.

경량·컴팩트 구조

컴팩트하고 경량화된 구조로 설계되어 협소한 공간에서도 고속 동작이 가능하며, 공간 활용도를 높입니다.

우수한 용접 품질

균일하고 안정적인 용접 비드를 구현하여 기공이나 균열 발생을 최소화하고, 고품질 용접 결과를 유지합니다.

적용분야

로보알바의 용접 로봇은 알루미늄 용접을 포함해 직선, 곡선, 복합 형상의 다양한 용접 공정에 적용할 수 있습니다. 자동차 부품, 오토바이, 보일러, 중장비, 철도 차량, 랙 및 프레임 구조물, 가구(테이블, 의자), 피트니스 장비, 도어 프레임 등 다양한 산업 분야의 용접 공정에서 활용됩니다.

콤팩트한 경량 디자인:가볍고 정밀한 기구부 설계로 빠른 가동 속도와 공간 효율성을 동시에 확보했습니다.

강력한 현장 적응력: 전용 보호 커버(Protective Cover)를 장착하면 분진이나 습기가 많은 가혹한 작업 환경에서도 고장 걱정 없이 안심하고 운용할 수 있습니다

사양

- 반복 정밀도 : ±0.03mm

- 작업 반경 : 1410.5m-

- 적용 소재: 탄소강, 스테인리스강, 알루미늄, 구리 등

- Multiterm exclusive patents, cost-effective beyond similar products.

- Joint gear gip adjustment, fine control, and quick dynamic response.

- Hollow joint support structure, with more rigid and better flexibility.

- Noise reduction structure, running sound Very soft.

- Repeat positioning accuracy: ±0.08mm

- Armspan: 1456mm

- Working piece: Carbon steel, stainless steel, aluminum, copper, etc

- Gear gaps adjustment structure, improve joint accuracy.

- Hollow structure with wrist U-shaped structure, improve joint support stiffness to make more flexibility.

- Special patent for noise reduction structure, reduce operating noise.

- Antishake optimization, reduce endclearance, improve operating stiffnessand reduce control error.

- Repeat positioning accuracy: ±0.08mm

- Armspan: 2014mm

- Working piece: Carbon steel, stainless steel, aluminum, copper, etc

EVS Pick and Place Robot Advantages

Well-Knit Design: EVS robots have slender designs which makes them more flexible in small spaces with very low collision rates.

Leak-Proof Structure: Our leak-proof pick & place robots are suitable even for oil-mist and dusty environments.

Easy Installation: With light structure design, they can be easily installed inside your system or mounted upside-down.

EVS Pick and Place Robot Applications

EVS robotic arms can handle various pick and place robot applications from simple to monotonous and repetitive tasks. When strategically positioned, they can provide impressive results for loading, unloading, feeding, packaging, assembly, palletizing, sorting, welding, deburring, and other material handling applications.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 700~3100mm

- Payload: 6~800kg

- The cobot arm is mainly used for handling, palletizing, pick and place, also arc welding, with high reliability and excellent performacne.

- This cobot is able to operate multiple procedure in narrow space, lightweight, compact structure.

- With collaborative feature, the cobot can extend your time and space, liberate human from repeat work and hazard enviroment.

- Repeat positioning accuracy: ±0.02mm

- Armspan: 900~1300mm

- payload:6~18kg

- This SCARA robot is with compact and flexible structure, fast running speed, high transmission accuracy and low noise.

- It can be applied in handling, packaging, assembly, 3C and other fields.

- Maximum Reach: 400~1000mm

- Max Payload: 3~20kg

EVS Assembly Robot Advantages

Flexible Design: EVS assembly robots have flexible and compact designs, giving you a large workspace.

Quick Installation: Installation of EVS robotic arms only takes a few hours with a straightforward debugging process.

High Load Capacity: Our robots have highly rigid arms that can handle large products without any complications.

EVS Assembly Robot Applications

EVS assembly line robotic arms are applicable for a wide variety of industrial processes aimed to expand your production capabilities. Save your workers from dull and tedious assembly line jobs as well as other applications such as sorting, handling, loading and unloading, welding spraying, polishing, palletizing, and 3C.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 700~3100mm

- Payload: 6~800kg

- The cobot arm is mainly used for handling, palletizing, pick and place, also arc welding, with high reliability and excellent performacne.

- This cobot is able to operate multiple procedure in narrow space, lightweight, compact structure.

- With collaborative feature, the cobot can extend your time and space, liberate human from repeat work and hazard enviroment.

- Repeat positioning accuracy: ±0.02mm

- Armspan: 900~1300mm

- payload:6~18kg

- This SCARA robot is with compact and flexible structure, fast running speed, high transmission accuracy and low noise.

- It can be applied in handling, packaging, assembly, 3C and other fields.

- Maximum Reach: 400~1000mm

- Max Payload: 3~20kg

EVS Handling Robot Advantages

Large Workspace: EVS robot arms have flexible and lightweight designs that allow for more working space in your production line.

Fast Response: The compact structure of our machines allows them to operate at fast speeds with high repeat positioning accuracy.

Low-Power Output: Our handling robots operate at low power outputs to help you save on your power consumption expenses.

EVS Handling Robot Applications

EVS’ material handling robots can be used for a wide variety of applications that are related to transporting objects. These applications encompass machine loading, packing, palletizing, transferring, and part selection as well as other hazardous and fatiguing tasks in the industrial environment.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 700~3100mm

- Payload: 6~800kg

- The cobot arm is mainly used for handling, palletizing, pick and place, also arc welding, with high reliability and excellent performacne.

- This cobot is able to operate multiple procedure in narrow space, lightweight, compact structure.

- With collaborative feature, the cobot can extend your time and space, liberate human from repeat work and hazard enviroment.

- Repeat positioning accuracy: ±0.02mm

- Armspan: 900~1300mm

- payload:6~18kg

- This SCARA robot is with compact and flexible structure, fast running speed, high transmission accuracy and low noise.

- It can be applied in handling, packaging, assembly, 3C and other fields.

- Maximum Reach: 400~1000mm

- Max Payload: 3~20kg

Cost Reduction: Automation in palletizing reduces dependence on manual labor, leading to lower labor costs. While the initial investment in palletizing robots may be higher, the long-term operational and maintenance costs are relatively low, providing significant cost advantages.

Enhanced Quality: Palletizing robots execute tasks with high precision, ensuring consistent product stacking. This minimizes losses and waste caused by human errors, thereby elevating the overall quality of the production line.

Increased Safety: Automated systems can operate in hazardous or challenging environments, reducing the risk of accidents associated with manual labor. This not only improves workplace safety but also mitigates health issues related to human labor.

Flexibility and Versatility: Palletizing robots often possess flexible programming and adaptive capabilities, allowing them to quickly adapt to different types and sizes of products. This flexibility makes them suitable for various stages of production and changing manufacturing demands.

Real-time Monitoring and Data Analysis: Palletizing robots are equipped with advanced sensors and monitoring systems for real-time tracking of the production process. Analyzing this data enables production managers to make informed decisions, optimizing production flow.

Promotion of Sustainability: By efficiently utilizing resources, reducing waste, and minimizing errors, palletizing robots contribute to the sustainability of the production line. This aids in minimizing the environmental impact associated with manufacturing processes.

Model | QJRB180-1 | QJR130-3100M | QJRB800-1 | QJR260-3100M |

Axis Number | 4 | 4 | 4 | 4 |

Payload | 180kg | 130kg | 800kg | 260kg/300kg |

Repeat Positioning | ±0.5mm | ±0.5mm | ±0.5mm | ±0.5mm |

Max Armspan | 3157mm | 3157mm | 3155mm | 3157mm |

Robot Body Weight | 1400kg | 1400kg | 2550kg | 1400kg |

Power Capacity | 17.4kVA | 17.4kVA | 39.6kVA | 19.2kVA |

Power Supply | Three phase 5 wire 380V ±10% | Three phase 5 wire 380V ±10% | Three phase 5 wire 380V ±10% | Three phase 5 wire 380V ±10% |

Cabinet Size | 600*480*920mm | 600*480*920mm | 600*480*920mm | 600*480*920mm |

Cabinet Weight | 110kg | 110kg | 110kg | 110kg |

Installing Form | Ground Mounted | Ground Mounted | Ground Mounted | Ground Mounted |

Application | It is suitable for punching machine, furniture, food and beverage, 3C and other industries. On Palletizing, picking up, packaging, handling, loading and unloading. | It is suitable for punching machine, furniture, food and beverage, 3C and other industries. On Palletizing, picking up, packaging, handling, loading and unloading. | Heavy-duty palletizing application. Such as brick factories palletizing. | It is suitable for punching machine, furniture, food and beverage, 3C and other industries. On Palletizing, picking up, packaging, handling, loading and unloading. |

Achieve the combined use of multiple spraying methods,such as gas spraying,electrostatic spraying,

Cyclone spraying, Paint atomization,magnetic control spraying,etc.

Model | QJR6-2700P | QJR20-1600(None Explosion-proof) | QJRP10-1(Explosion-proof) |

Axis Number | 6 | 6 | 6 |

Payload | 6kg | 20kg | 10kg |

Repeat Positioning | ±0.5mm | ±0.05mm | ±0.5mm |

Max Armspan | 2701mm | 1668mm | 2035mm |

Robot Body Weight | 400kg | 270kg | 370kg |

Power Capacity | 4.4kVA | 3.7kVA | 4.4kVA |

Power Supply | One phase 220V ±10% | One phase 220V | One phase 220V ±10% |

Cabinet Size | 600*480*1270mm | 600*480*920mm | 600*480*1270mm |

Cabinet Weight | 120kg | 95kg | 120kg |

Installing Form | Ground Mounted | Ground Mounted/ wall mounted | Ground Mounted |

Application | For painting, there is no singularity point, making the teaching programming much easier. | loading and unloading, handling, sorting, assembly etc. | For painting, there is no singularity point, making the teaching programming much easier. |

Industrial Painting Robot:

First Certified

First certified painting robot in China with an explosion-proof feature.

Model | QJR20-2000 | QJR25-1800 | QJR30-1600 |

Axis Number | 6 | 6 | 6 |

Payload | 20kg | 25kg | 20/30kg |

Repeat Positioning | ±0.5mm | ±0.05mm | ±0.5mm |

Max Armspan | 2001mm | 1852mm | 1668mm |

EVS Polishing Robot Advantages

Less Configuration Time: Our robots are easy to maintain and operate and can be programmed offline which significantly reduces on-site configuration time.

High Grinding Quality: They are equipped with grinding tools that can produce constant output to ensure consistent and thorough product finishes.

Effective Dust Isolation: EVS polishers can effectively recover and isolate metal dust without manual contact for a more improved working environment.

EVS Polishing Robot Applications

Our polishing robotic arms can be used for cookware, motorcycles, automotive, home appliances, and other metal parts. With their capability to be reprogrammed, they can also be used for handling other industrial robotic applications aside from polishing like palletizing, packaging, painting, welding, assembly, and others.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 700~3100mm

- Payload: 6~800kg

- The cobot arm is mainly used for handling, palletizing, pick and place, also arc welding, with high reliability and excellent performacne.

- This cobot is able to operate multiple procedure in narrow space, lightweight, compact structure.

- With collaborative feature, the cobot can extend your time and space, liberate human from repeat work and hazard enviroment.

- Repeat positioning accuracy: ±0.02mm

- Armspan: 900~1300mm

- payload:6~18kg

EVS Delta Sorting Robot Arms Advantages

High Positioning Accuracy: EVS robots have a simple operation that can perform automatic sorting with high positioning accuracy.

Added Vision Technologies: Our machines are equipped with various vision systems and sensors to help distinguish different shapes, colors, and sizes.

Programmable Pattern: You can easily reprogram our delta robots to match your required sorting patterns in different applications.

EVS Delta Sorting Robot Arms Applications

EVS delta sorting robots are ideal for packaging and picking small and lightweight objects at high speeds in your production line. They can complete dynamic tracking, object placement, pick-up, handling, packaging, and assembly applications for food, medicines, 3C, toiletries, and others.

Real-time data monitoring: With the help of Internet of Things technology, smart warehouses can monitor the location, temperature, humidity and other information of goods in real time, improving the accuracy and efficiency of smart warehousing management.

Artificial Intelligence Optimization: Smart warehouses use artificial intelligence technology to analyze large amounts of data, optimize smart warehousing processes and cargo distribution routes, and improve overall operational efficiency.

Flexible adaptability: The smart warehouse adopts a modular design and can be flexibly configured according to different business needs to better adapt to market changes and enterprise development

Model | QJRB180-1 | QJR130-3100M | QJRB800-1 | QJR260-3100M |

Axis Number | 4 | 4 | 4 | 4 |

Payload | 180kg | 130kg | 800kg | 260kg/300kg |

Repeat Positioning | ±0.5mm | ±0.5mm | ±0.5mm | ±0.5mm |

Max Armspan | 3157mm | 3157mm | 3155mm | 3157mm |

Robot Body Weight | 1400kg | 1400kg | 2550kg | 1400kg |

Power Capacity | 17.4kVA | 17.4kVA | 39.6kVA | 19.2kVA |

Power Supply | Three phase 5 wire 380V ±10% | Three phase 5 wire 380V ±10% | Three phase 5 wire 380V ±10% | Three phase 5 wire 380V ±10% |

Cabinet Size | 600*480*920mm | 600*480*920mm | 600*480*920mm | 600*480*920mm |

Cabinet Weight | 110kg | 110kg | 110kg | 110kg |

Installing Form | Ground Mounted | Ground Mounted | Ground Mounted | Ground Mounted |

Application | It is suitable for punching machine, furniture, food and beverage, 3C and other industries. On Palletizing, picking up, packaging, handling, loading and unloading. | It is suitable for punching machine, furniture, food and beverage, 3C and other industries. On Palletizing, picking up, packaging, handling, loading and unloading. | Heavy-duty palletizing application. Such as brick factories palletizing. | It is suitable for punching machine, furniture, food and beverage, 3C and other industries. On Palletizing, picking up, packaging, handling, loading and unloading. |

EVS Machine Tending Robot Advantages

Repeatable Accuracy: Industrial machine tending robots are capable of achieving highly accurate results to improve your production quality.

Improved Uptime: Create better ergonomic conditions and minimize human error while improving uptime drastically compared to manual processes.

High Payload Capacity: With rigid arms and high payload capacities, our robots can be used in a wide variety of machine tending applications.

EVS Machine Tending Robot Applications

You can use EVS machine tending robots for loading and unloading parts in applications such as grinding, injection molds, compression molds, welding, stamping, forging, trimming, punching, milling, and turning. Aside from machine tending processes, our robots are also suitable for packaging, assembly, palletizing, and painting applications.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 700~3100mm

- Payload: 6~800kg

- The cobot arm is mainly used for handling, palletizing, pick and place, also arc welding, with high reliability and excellent performacne.

- This cobot is able to operate multiple procedure in narrow space, lightweight, compact structure.

- With collaborative feature, the cobot can extend your time and space, liberate human from repeat work and hazard enviroment.

- Repeat positioning accuracy: ±0.02mm

- Armspan: 900~1300mm

- payload:6~18kg

EVS Gluing Robot Advantages

Robust Structure: EVS gluing robots have individual inteligence property design. They are more flexible and accurate and reliable.

High Quality Components: EVE gluing robots use one of the most famous reducer and motor to make the robot body, the quality are better than most of the other Chinese brand robot manufacturer.

Multiple Choice for Control System: EVS gluing robot have two options for control system to meet different applications. You can choose our self-developed control system and also you can choose KEBA controller.

Gluing Robot Applications

EVS gluing robot can be applied in 3C products sealing and conducting resin gluing, thermal insulation resin gluing, etc. You can use in 3C industry, household appliances, car coponents, etc.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 700~3100mm

- Payload: 6~800kg

- The cobot arm is mainly used for handling, palletizing, pick and place, also arc welding, with high reliability and excellent performacne.

- This cobot is able to operate multiple procedure in narrow space, lightweight, compact structure.

- With collaborative feature, the cobot can extend your time and space, liberate human from repeat work and hazard enviroment.

- Repeat positioning accuracy: ±0.02mm

- Armspan: 900~1300mm

- payload:6~18kg

F. 051-7413985

mail@roboalba.kr